In the competitive and high-stakes world of aerospace engineering, the quality and reliability of components are paramount. The intricacies of aircraft and spacecraft demand parts that meet the highest standards of precision and durability. This is where aerospace parts manufacturing shines, playing a crucial role in ensuring the safety and efficiency of aerospace vehicles. At General A&E Manufacturing, we pride ourselves on being at the forefront of this essential industry, delivering top-notch components that meet the rigorous demands of modern aviation and space exploration.

The Importance of Aerospace Parts Manufacturing

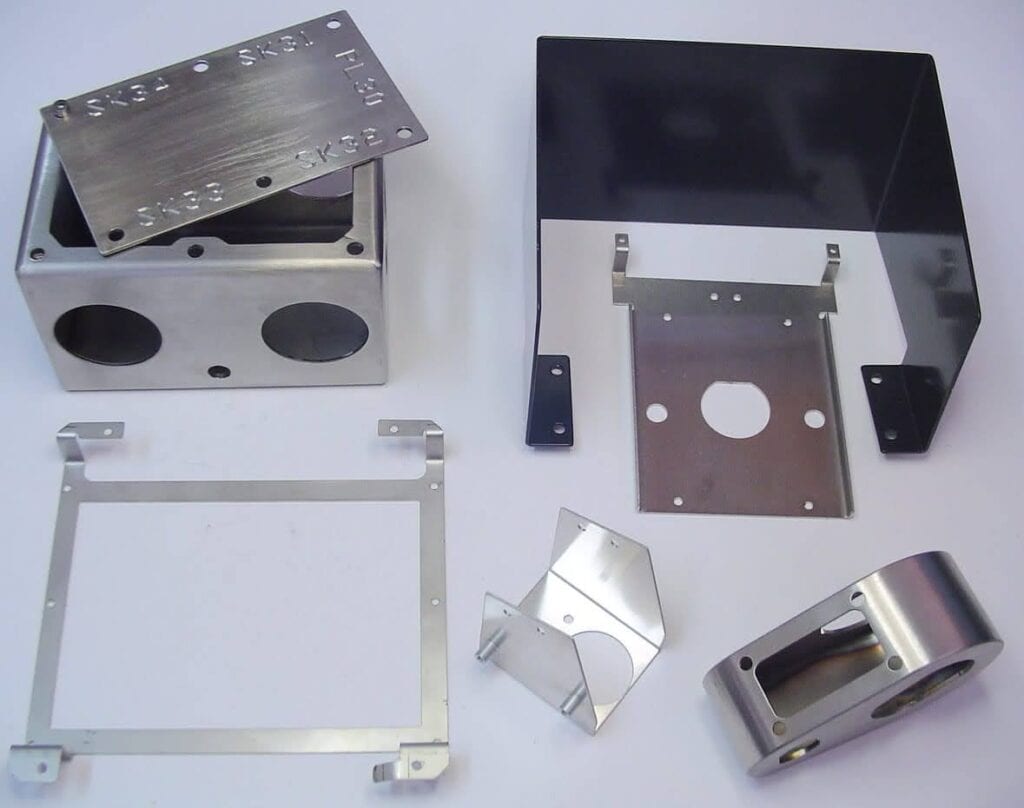

Aerospace parts manufacturing involves the production of various components used in aircraft and spacecraft, including structural parts, engine components, avionics housings, and more. These parts must adhere to exact specifications and withstand extreme conditions, making precision and quality control critical aspects of the manufacturing process.

At General A&E, we understand the vital role these components play. Our commitment to excellence in aerospace parts manufacturing ensures that every piece we produce contributes to the overall safety and performance of the aircraft. We specialize in creating custom solutions tailored to the unique needs of our clients, ensuring that each part meets or exceeds industry standards.

Advanced Technology and Equipment

To deliver the highest quality components, General A&E utilizes state-of-the-art technology and equipment. Our facility is equipped with advanced machinery that allows us to achieve the precision required in aerospace parts manufacturing. This includes CNC-controlled punch presses, precision bending machines, and other specialized equipment designed to handle complex geometries and tight tolerances.

One of our key strengths is our ability to work with a wide range of materials commonly used in aerospace applications, including aluminum, stainless steel, and titanium. Our advanced equipment and skilled technicians ensure that we can handle any project, no matter how challenging.

Skilled Workforce

While advanced technology is essential, the expertise of our workforce is equally important. At General A&E, we take pride in our team of highly skilled professionals who bring years of experience and technical knowledge to every project. Our technicians are trained to operate sophisticated machinery and understand the intricacies of aerospace parts manufacturing.

Each project begins with a thorough review of the client’s specifications and requirements. Our engineers and technicians collaborate closely to develop a detailed plan, ensuring that every aspect of the manufacturing process is carefully considered. This collaborative approach allows us to identify potential challenges early on and implement solutions that guarantee the highest quality results.

Quality Assurance in Aerospace Parts Manufacturing

Quality assurance is a cornerstone of aerospace parts manufacturing at General A&E. We adhere to strict quality control procedures throughout every stage of the manufacturing process, from initial design to final inspection. Our commitment to quality is underscored by our ISO 9001:2015 and AS9100 certifications, which demonstrate our dedication to meeting the highest standards of excellence.

Recently, we have also achieved NADCAP certification for welding, further highlighting our commitment to quality and precision. NADCAP, or the National Aerospace and Defense Contractors Accreditation Program, is a prestigious accreditation that signifies our compliance with the highest standards in the aerospace and defense industries. This certification is particularly important for processes like welding, where precision and reliability are critical.

Every component we produce undergoes rigorous testing and inspection to ensure it meets the required specifications. This includes dimensional checks, material analysis, and performance testing. Our quality assurance team utilizes advanced metrology equipment to verify that each part conforms to the precise measurements and tolerances specified by the client. By maintaining a robust quality management system, we ensure that our clients receive components that are reliable, safe, and ready for use in critical aerospace applications.

Custom Solutions for Aerospace Parts Manufacturing

One of the strengths of General A&E is our ability to provide custom manufacturing solutions tailored to the specific needs of our clients. We understand that aerospace projects often involve unique challenges and requirements, and we are equipped to handle even the most complex manufacturing tasks.

Our team works closely with clients to develop custom solutions that address their unique needs. This includes everything from initial design and prototyping to full-scale production. We leverage our expertise in aerospace parts manufacturing to deliver components that meet the exact specifications and performance criteria required by our clients. Whether it’s producing a single prototype or managing a large production run, we have the capabilities and experience to deliver outstanding results.

Supporting the Aerospace Industry

At General A&E, we are proud to support a wide range of clients in the aerospace industry. Our manufacturing services are utilized by leading aerospace manufacturers, defense contractors, and space exploration companies. We have a proven track record of delivering high-quality components that contribute to the success of critical aerospace projects.

One of our notable areas of expertise is the production of components for aircraft engines. These parts must withstand extreme temperatures and pressures, making precision and durability paramount. Our advanced manufacturing capabilities allow us to produce engine components that meet the stringent requirements of the aerospace industry, ensuring reliable performance and long-term durability.

In addition to engine components, we also specialize in the production of structural parts, avionics housings, and other critical components. Our diverse capabilities and commitment to quality make us a trusted partner for aerospace companies seeking reliable manufacturing solutions.

The Future of Aerospace Parts Manufacturing

As the aerospace industry continues to evolve, the demand for high-precision parts manufacturing solutions will only grow. At General A&E, we are committed to staying at the forefront of this industry by continually investing in new technologies and enhancing our capabilities. We understand that the future of aerospace parts manufacturing lies in the ability to produce increasingly complex and precise components, and we are dedicated to meeting this challenge.

In the coming years, we plan to expand our capabilities further by incorporating advanced automation and digital manufacturing technologies. These advancements will allow us to increase efficiency, reduce lead times, and deliver even higher levels of precision. By embracing innovation and staying ahead of industry trends, we will continue to provide our clients with the best manufacturing solutions available.

For companies seeking top-tier aerospace parts manufacturing solutions, General A&E Manufacturing stands out as a leader in the industry. Our combination of advanced technology, skilled technicians, and unwavering commitment to quality makes us the ideal partner for aerospace projects of all sizes. Whether you need custom engine components, structural parts, or avionics housings, we have the expertise and experience to deliver exceptional results.

Discover how General A&E’s dedication to precision and innovation can elevate your aerospace projects to new heights. Contact us today to learn more about our manufacturing capabilities and how we can support your specific needs. Together, we can achieve excellence in aerospace parts manufacturing.