Sheet metal fabrication involves manipulating flat sheets of metal using techniques such as cutting, bending, forming, and more to create individual components for a specific product. These components can then be assembled into the final product via welding, rivets, adhesives, or fasteners. At General A&E, we’ve been providing precision sheet metal fabrication and assembly services since 1954. Using advanced automated equipment, we can deliver high-quality parts and finished products that meet your tight-tolerance requirements.

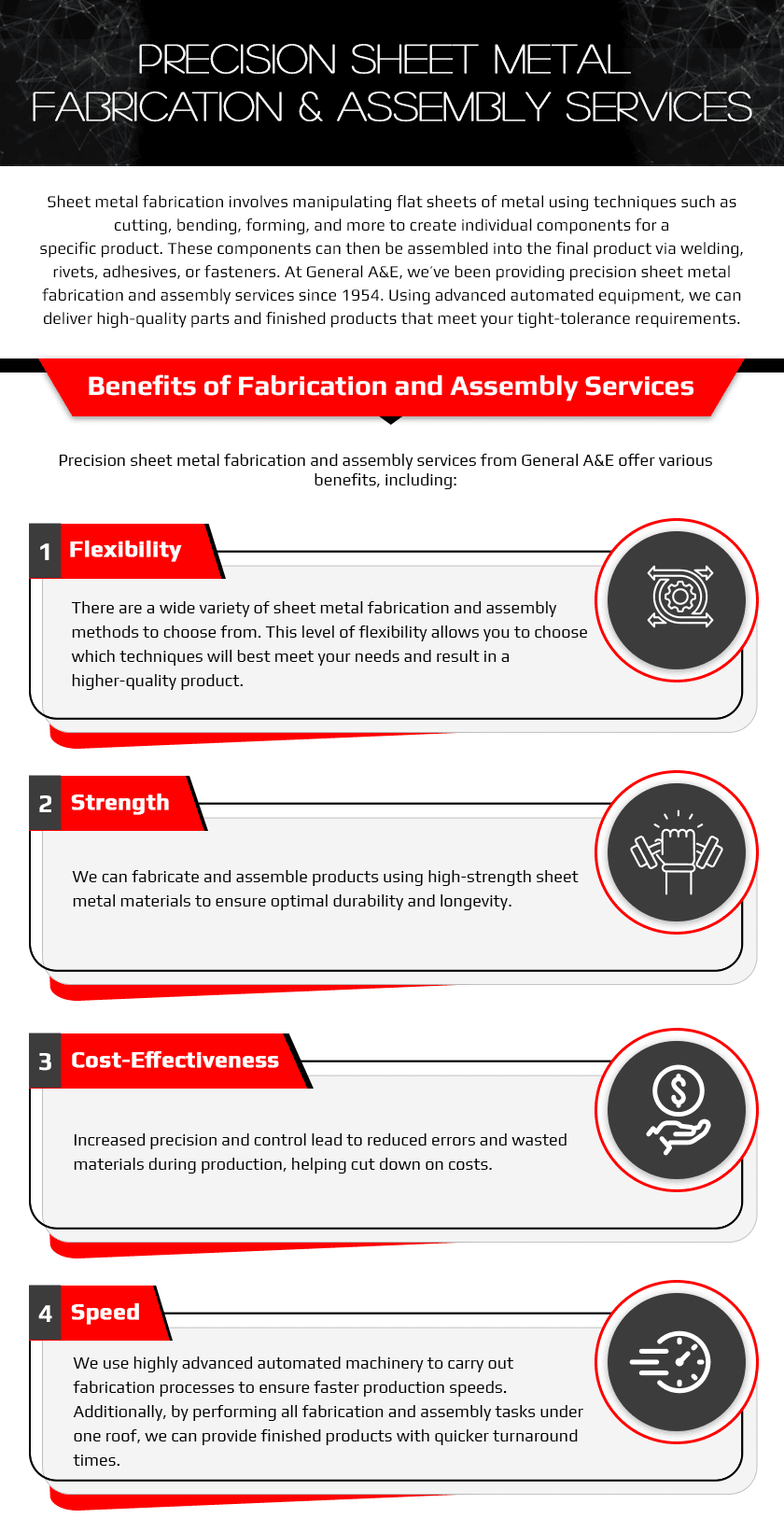

Benefits of Fabrication and Assembly Services

Precision sheet metal fabrication and assembly services from General A&E offer various benefits, including:

- Flexibility. There are a wide variety of sheet metal fabrication and assembly methods to choose from. This level of flexibility allows you to choose which techniques will best meet your needs and result in a higher-quality product.

- Strength. We can fabricate and assemble products using high-strength sheet metal materials to ensure optimal durability and longevity.

- Cost-Effectiveness. Increased precision and control lead to reduced errors and wasted materials during production, helping cut down on costs.

- Speed. We use highly advanced automated machinery to carry out fabrication processes to ensure faster production speeds. Additionally, by performing all fabrication and assembly tasks under one roof, we can provide finished products with quicker turnaround times.

Our Precision Sheet Metal Fabrication and Assembly Capabilities

Precision sheet metal fabrication involves numerous processes that can be combined to create the desired part. These processes include everything from bending and cutting to punching, forming, and more. At General A&E, we have the expertise and experience to fabricate and assemble sheet metal products of all sizes and complexities. Our specific capabilities include:

- Cutting. This process involves cutting sheet metal materials into the desired shape. We use advanced laser cutting machinery to ensure precise and accurate cuts every time.

- Bending. Sheet metal bending is a process that involves applying pressure to the metal, causing it to bend into a ‘V’ or ‘U’ shape. Our computer-controlled bending equipment can process parts with multiple bends that meet all your dimensional tolerance requirements.

- Forming. The forming process may involve drawing, bending, punching, or stretching metal sheets to shape them into various forms based on your specifications.

- Welding. This process entails fusing multiple parts together using heat and pressure. This joining method is ideal for applications requiring a durable and permanent assembly.

- Assembly. In addition to welding, we also join or assemble multiple components together using PEM nuts, rivets, adhesives, and other types of standard or mil-spec hardware. We also offer silk screening, stenciling, and rubber stamping services to ensure we deliver a completely assembled, finished product.

Precision Sheet Metal Assembly Services by General A&E

Sheet metal fabrication and assembly processes offer a range of benefits that make them an ideal choice for producing various types of products. At General A&E, we can provide precision sheet metal fabrication and assembly solutions based on our customers’ individual requirements. By combining both fabrication and assembly capabilities under one roof, we can ensure faster lead times and a higher-quality end product.

For more information about our precision sheet metal fabrication and assembly services, request a quote today and we’ll connect you with an expert.