Similar to welding, brazing is distinguished by the use of a filler metal with a lower melting point to bond the two metal surfaces to create a joint. This makes brazing welding an excellent choice for applications where the high temperatures associated with other welding processes could compromise the structural integrity or alter the material properties of the component.

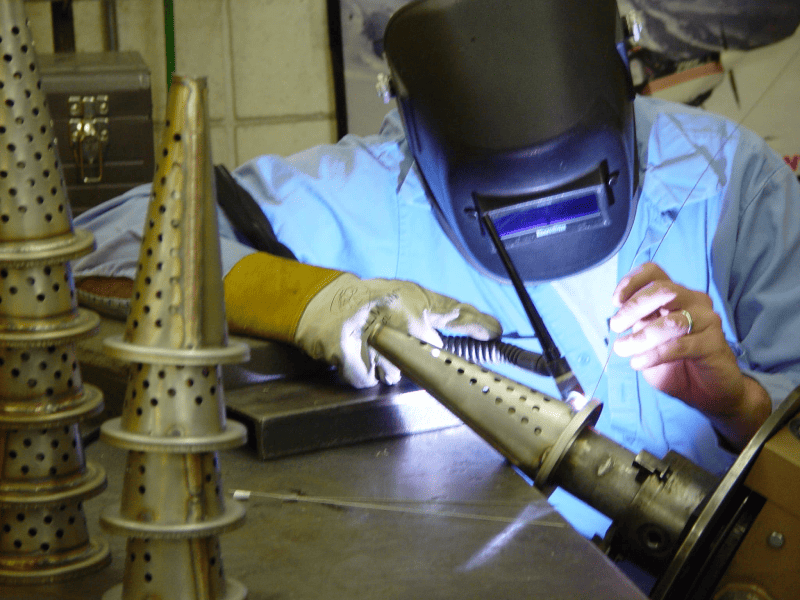

What is Brazing in Welding?

Brazing is the process of bonding two pieces of metal using a filler material with a lower melting point than that of the base metals. As the filler metal is melted, it flows into the joint, bonding the base metals together. Braze welding is distinctive in that the low melting point causes no significant melting or fusion of the base material. It relies on the capillary attraction that draws filler metal into the joint to make a strong and leak-proof connection.

Creating a braze weld is similar in process to soldering, but it requires a higher melting point to form a stronger bond. It’s often used to join dissimilar metals together or in complex work environments that require the joining of pipes or tubes.

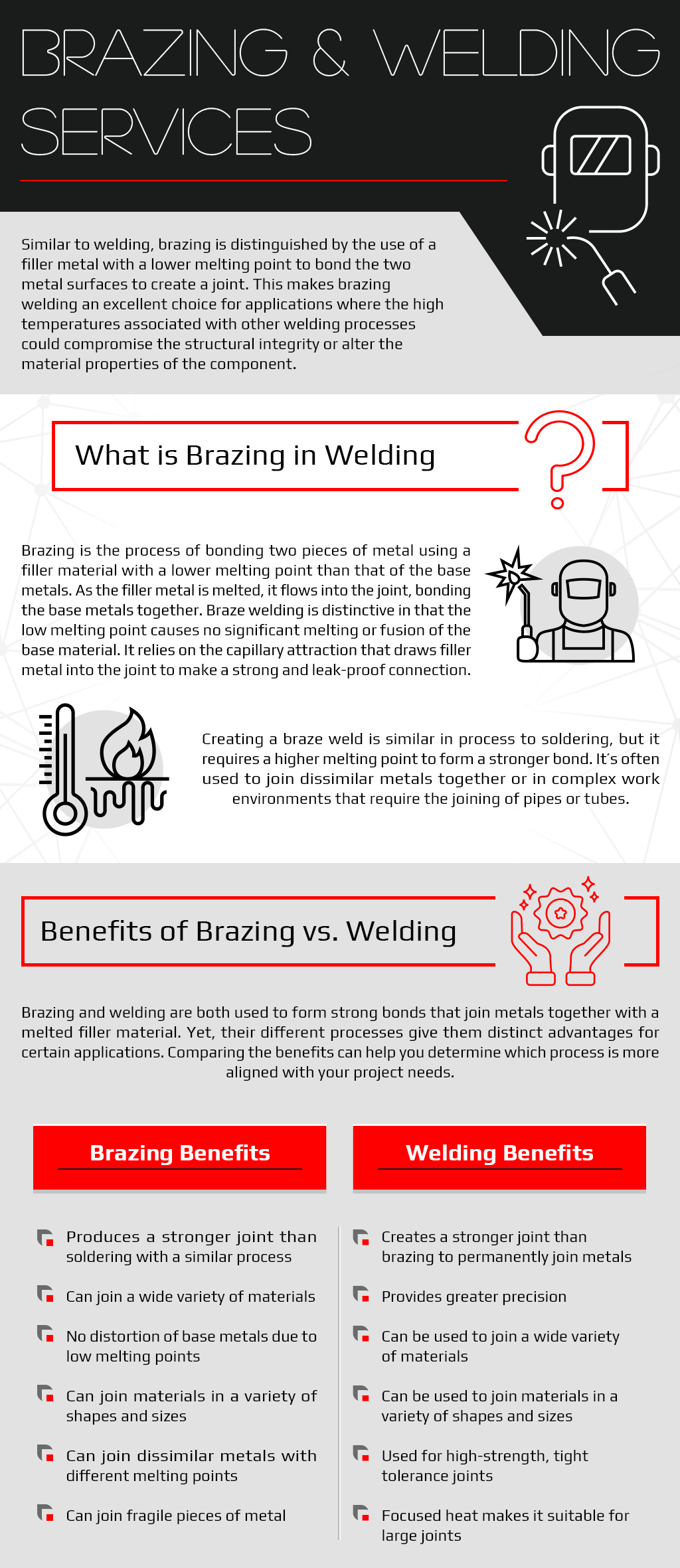

Benefits of Brazing vs. Welding

Brazing and welding are both used to form strong bonds that join metals together with a melted filler material. Yet, their different processes give them distinct advantages for certain applications. Comparing the benefits can help you determine which process is more aligned with your project needs.

Brazing Benefits

- Produces a stronger joint than soldering with a similar process

- Can join a wide variety of materials

- No distortion of base metals due to low melting points

- Can join materials in a variety of shapes and sizes

- Can join dissimilar metals with different melting points

- Can join fragile pieces of metal

Welding Benefits

- Creates a stronger joint than brazing to permanently join metals

- Provides greater precision

- Can be used to join a wide variety of materials

- Can be used to join materials in a variety of shapes and sizes

- Used for high-strength, tight tolerance joints

- Focused heat makes it suitable for large joints

Our Brazing vs. Welding Capabilities

Brazing and welding are both very effective ways to join metal. Different processes are ideal for specific applications. General A&E provides a diverse range of services tailored to meet the requirements of different industries and applications. This ensures our welders are equipped to work with a range of material types and thicknesses.

We offer a wide range of brazing and welding services, including:

- Torch Brazing

- Furnace Brazing

- Induction Brazing

- Dipped Brazing

- Resistance Brazing

- MIG Welding

- TIG Welding

- Stick Welding

- Plasma Arc Welding

- Spot Welding

At General A&E, we can produce dip-brazed assemblies such as chassis, cold walls, heat exchangers, and others. We are certified to AWS D17.1 standards, and we are proud to be approved welders for companies like Raytheon and Sikorsky.

Welding & Brazing Services by General A&E

Welding and braze welding are essential metal fabrication services used across many industries from plumbing to aerospace. To meet the varied needs of our clients, the skilled welders at General A&E offer a wide range of services that encompass a wide range of material types and thicknesses. With nearly 7 decades of industry experience, we can handle the most complex projects and tackle the most difficult assemblies. Get in touch to talk with a member of the team about your welding and brazing needs or request a quote for the services you need.