Aerospace and Defense Manufacturing: Why General A&E is Your Trusted Partner

Leave a CommentWhen it comes to aerospace and defense manufacturing, precision and reliability are non-negotiable. Every part, every weld, and every component plays a critical role in ensuring the safety, performance, and success of high-stakes projects. At General A&E, we’ve been delivering top-tier manufacturing solutions since 1954, partnering with some of the biggest names in aerospace and defense. With a legacy of excellence and a commitment to innovation, we’re proud to support the industries that keep our world moving forward.

What Sets Aerospace and Defense Manufacturing Apart?

Manufacturing for the aerospace and defense industries is unlike any other sector. These industries demand uncompromising quality and attention to detail. The components produced must withstand extreme conditions—high altitudes, intense speeds, and challenging environments. There’s zero room for error when it comes to safety and performance.

At General A&E, we understand these challenges. That’s why we’ve built our reputation on precision engineering, certified quality processes, and a team of experts who know how to meet the unique demands of aerospace and defense manufacturing.

Certifications That Matter: NADCAP and AS9100

One of the key factors that sets General A&E apart from other manufacturers is our commitment to quality, backed by industry-leading certifications.

NADCAP Certification for Welding

Our NADCAP certification for welding is a testament to our expertise and ability to meet the highest standards in the aerospace and defense industries. This certification ensures that our welding processes are reliable, consistent, and meet the rigorous demands of these sectors. For projects that require the utmost precision, our NADCAP certification provides peace of mind.

AS9100 and ISO 9001:2015 Certifications

We also hold AS9100 and ISO 9001:2015 certifications, underscoring our commitment to maintaining a strong quality management system. These certifications demonstrate that our processes are continuously evaluated and improved to meet or exceed the highest industry standards. Whether we’re producing parts for a commercial aircraft or a military defense system, our clients can trust that we’ll deliver components that perform flawlessly.

Advanced Technology for Superior Results

In aerospace and defense manufacturing, technology plays a crucial role in ensuring accuracy and efficiency. At General A&E, we’ve invested in state-of-the-art equipment to handle even the most complex manufacturing tasks.

CNC-Controlled Punch Presses and Precision Bending

Our facility is equipped with advanced CNC-controlled punch presses and precision bending machines. This technology allows us to work with a variety of materials, including aluminum, stainless steel, and titanium, to create components with tight tolerances. Our precision bending capabilities ensure that every part is shaped to exact specifications, no matter how complex the geometry.

Robotic Welding with ARCweld by MotionMan

For welding projects, we rely on ARCweld by MotionMan, a cutting-edge robotic welding system that delivers flawless welds with exceptional consistency. Robotic welding allows us to maintain the highest level of accuracy while ensuring efficiency and speed—critical factors for aerospace and defense manufacturing.

Advanced Laser Cutting with the LC 2012 C1

Our LC 2012 C1 laser cutting machine combines laser precision with punching capabilities, making it ideal for projects that require detailed features and complex shapes. This machine allows us to produce high-quality parts quickly and accurately, ensuring that our clients receive components that are ready for the rigors of aerospace and defense applications.

Custom Solutions for Aerospace and Defense Projects

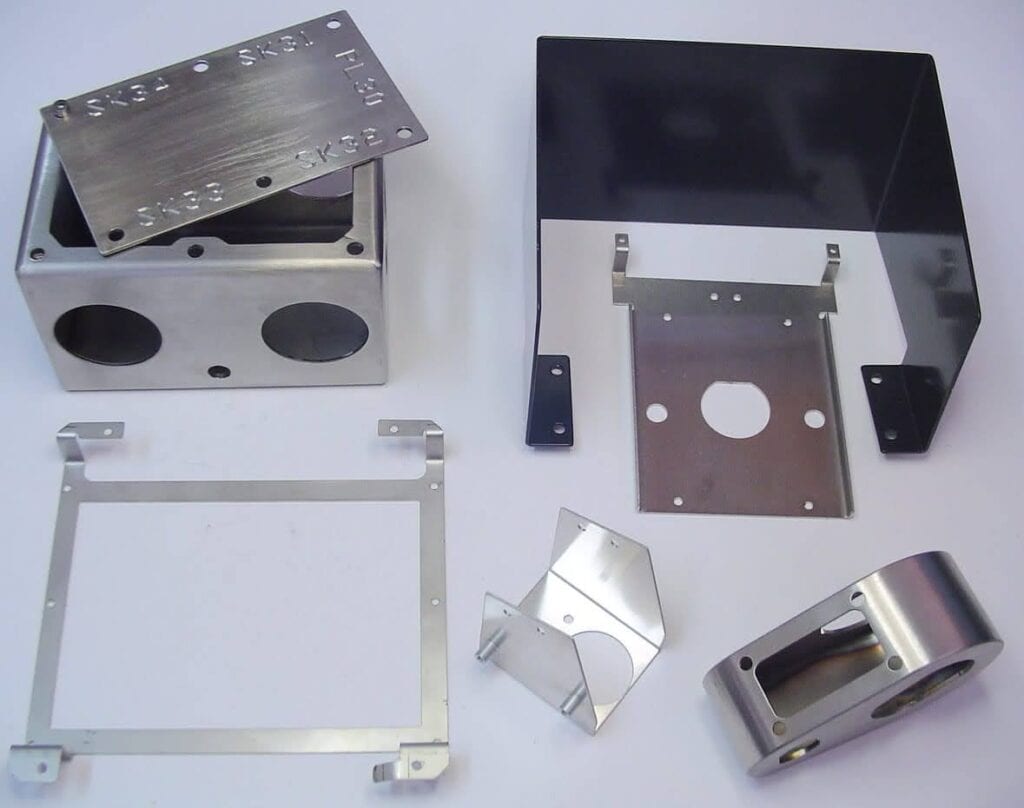

Every aerospace and defense project is unique, and that’s where General A&E’s expertise truly shines. We specialize in providing custom manufacturing solutions that meet the specific needs of each client.

Whether it’s producing a prototype or scaling up to full production, we work closely with our clients to ensure that every component meets their exact specifications. Our engineers and technicians are experts in problem-solving, and we thrive on tackling challenging projects that require innovative solutions.

From designing custom metal enclosures to fabricating intricate aerospace components, General A&E has the experience and capabilities to handle a wide range of projects. We understand the high standards of aerospace and defense manufacturing, and we’re committed to delivering results that exceed expectations.

Supporting Both Commercial and Military Aerospace

At General A&E, we’re proud to support both commercial aerospace and military defense projects. Each sector has its own unique challenges and requirements, and we’re equipped to handle them all.

For our commercial aerospace clients, we provide components that are critical to the safety and performance of aircraft. Our precision sheet metal fabrication and welding services ensure that every part is manufactured to the highest quality standards, helping our clients meet their production and safety goals.

On the military defense side, we’ve built strong relationships with defense contractors who rely on us to produce components that can withstand the toughest conditions. From military aircraft parts to custom defense equipment, our manufacturing processes are designed to meet the stringent demands of military projects.

Why Choose General A&E for Aerospace and Defense Manufacturing?

With so many manufacturers in the industry, why choose General A&E? The answer lies in our unwavering commitment to quality, our advanced capabilities, and our proven track record.

Certified Quality: Our NADCAP, AS9100, and ISO 9001:2015 certifications ensure that every part we produce meets the highest industry standards.

Advanced Technology: We use the latest technology, including robotic welding and precision laser cutting, to deliver superior results.

Custom Solutions: We work closely with our clients to provide tailored manufacturing solutions that meet their exact needs.

Experience: With over 60 years of experience, we’ve developed a deep understanding of the aerospace and defense industries.

Reliability: We pride ourselves on delivering high-quality parts on time, every time. Our clients trust us to support their most critical projects, and we don’t take that responsibility lightly.

The Future of Aerospace and Defense Manufacturing

As the aerospace and defense industries continue to evolve, so too does the demand for advanced manufacturing solutions. At General A&E, we’re committed to staying at the forefront of these industries by continually investing in new technology, expanding our capabilities, and refining our processes.

We believe that the future of aerospace and defense manufacturing lies in precision, innovation, and collaboration. By working closely with our clients and staying ahead of industry trends, we’re confident that General A&E will continue to play a leading role in these critical industries.

For companies seeking a trusted partner in aerospace and defense manufacturing, General A&E is the clear choice. With our certified quality, advanced technology, and commitment to custom solutions, we have the expertise and experience to support your most challenging projects.

Contact us today to learn more about how we can support your aerospace or defense manufacturing needs. Together, we can achieve excellence in the industries that shape our world.

In the heart of New Jersey, precision metal fabrication is reaching new heights, thanks to industry leaders like General A&E Manufacturing. With their commitment to quality and excellence, General A&E proudly upholds the ISO 9001:2015 certification, a testament to their dedication to precision and customer satisfaction. This blog post explores the significance of ISO 9001:2015 precision metal fabrication in New Jersey and how General A&E is setting the standard in this critical industry.

In the heart of New Jersey, precision metal fabrication is reaching new heights, thanks to industry leaders like General A&E Manufacturing. With their commitment to quality and excellence, General A&E proudly upholds the ISO 9001:2015 certification, a testament to their dedication to precision and customer satisfaction. This blog post explores the significance of ISO 9001:2015 precision metal fabrication in New Jersey and how General A&E is setting the standard in this critical industry.

When it comes to aerospace manufacturing, precision and reliability are paramount. In the heart of New Jersey, General A&E Manufacturing stands out as a leader in aerospace metal enclosure manufacturing. This blog post delves into the factors that set General A&E apart and how their commitment to quality and innovation ensures that they remain a top choice for aerospace companies looking for exceptional metal enclosures.

When it comes to aerospace manufacturing, precision and reliability are paramount. In the heart of New Jersey, General A&E Manufacturing stands out as a leader in aerospace metal enclosure manufacturing. This blog post delves into the factors that set General A&E apart and how their commitment to quality and innovation ensures that they remain a top choice for aerospace companies looking for exceptional metal enclosures.